News

Teledyne CARIS announces release of HIPS and SIPS 10

Teledyne CARIS™ is pleased to announce the release of HIPS and SIPS™ 10. This release introduces exciting new capabilities for automation, efficiency, and usability through the integration of the Process Designer and the simultaneous introduction to the first commercially available solution for generating Variable Resolution (VR) Surfaces from source data.

Streamlining Automation with Process Designer

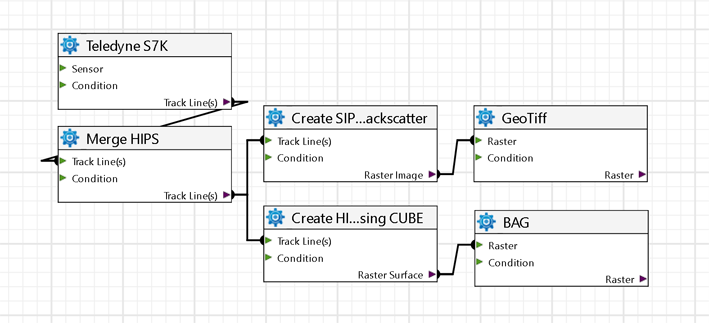

Inspired by CARIS Onboard™, the Batch Processor has been replaced with the new Process Designer. It provides access to the most important HIPS and SIPS processes including bathymetry and imagery workflows, base surfaces, mosaic, and VR surface creation.

The Process Designer allows users to create customized workflows directly tailored for their needs to save, share, and execute automatically. This addition offers users complete end-to-end control of processing through automation, thus minimizing the chance of erroneous steps and maximizing time management.

The drag and drop concept, which is the basis of the Process Designer, acts as a graphical interface for users. This creates the ability to build pre-defined and parallel workflows for the first time.

Example of a Process Designer workflow

Defined workflows will drive consistency through your organization by ensuring that all users work under the same parameters to achieve stable and consistent final deliverables. One single, automated sequence ensures that raw sensor data can be processed consistently and in a shorter period of time.

Integrating the Process Designer with CARIS HIPS and SIPS makes running even the most complex workflows as simple as pressing a play button, while providing absolute flexibility to those users who need total control over their data.

Seamless Product Creation with Variable Resolution (VR) Surfaces

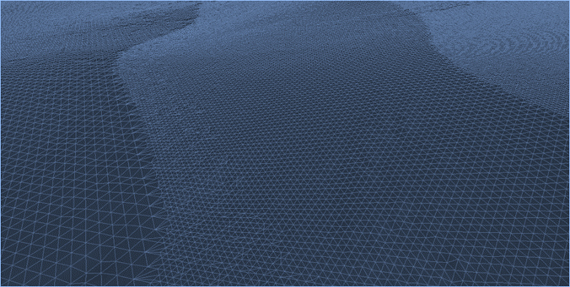

A VR Surface is a new digital elevation model (DEM) concept where the grid resolution varies in different areas to better reflect the shape and details of the seafloor. This allows a more dynamic and continuous model, quickly adapting to different data densities, leading to workflow efficiencies and improved data management and analysis.

Interaction with a VR Surface is a very fast process which seamlessly transitions between display scales, dynamically loading and unloading points as you zoom in further.

Resolution variability can be based on depth range or data density. Using depth range, the user will assign resolutions to a series of depth ranges. Typically, data from deep areas with fewer samples will be assigned a coarser resolution, with the assigned resolution becoming finer in shallower depths where more data is present. A slightly different approach is taken with the density technique. The user will define a target density value for each node and the algorithm will choose the resolution for each area that best meets that criteria. This removes any a priori assumptions about resolution by the user, producing a continuous model with an optimal resolution for each area, regardless of depth or data density.

VR surface created with HIPS and SIPS 10

A VR surface can be contoured in a single pass. This saves a great deal of time as traditionally, multiple surfaces would need to be generated and contoured. These contours would then require stitching together into single continuous line features and related depth areas.

Storage of such large datasets is accomplished through the CARIS Spatial Archive (CSAR™) Framework. It acts as a single file storage format for gridded, point cloud, and variable resolution data. It is scalable to billions of grid nodes and terabytes of data. This format is a very efficient way of storing and visualizing huge volumes of data.

To see if the new VR Surface capabilities can benefit your bathymetric workflow, we are providing a FREE 30-day evaluation of HIPS and SIPS 10. To secure your evaluation please email [email protected] today.

Join our Mailing List

Subscribe to email announcementsOur Latest Tweets

Tweets by Teledyne CARIS Follow us on TwitterConnect With Us